Mission

AXOR INDUSTRY

A fast-growing international company that went a long way from a distributor of hardware for PVC windows to a world-known manufacturer.

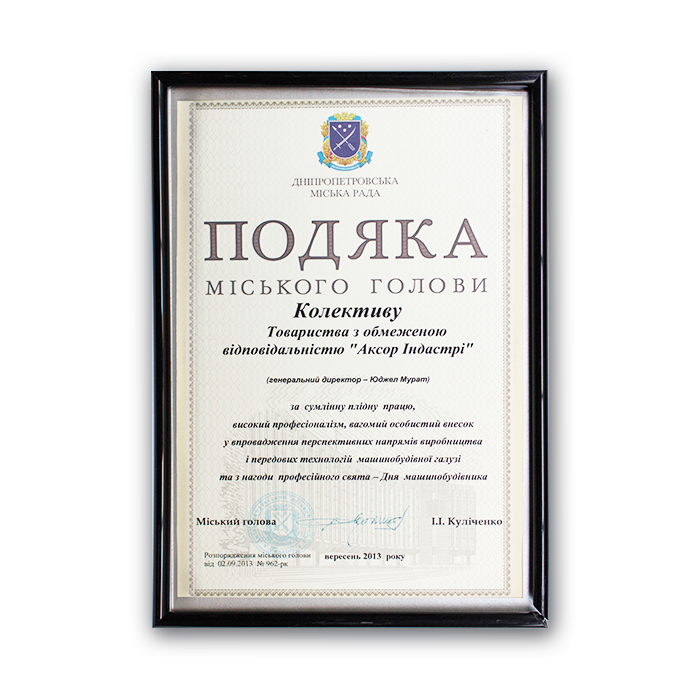

Today, our company has own modern plant in Dnipro, Ukraine, producing window and door hardware. The AXOR plant represents the №1 full-cycle production complex in Ukraine and one of the industry’s largest plants in Eastern Europe.

All production processes at the plant are fully automated, organized with environmental safety requirements and EN and DIN standards, and have been certified by IFT Rosenheim (Germany), the industry’s leading institute. Quality control is implemented at all production stages, and includes product testing at our own certified laboratory.

All products of AXOR INDUSTRY are conforms with DSTU, GOST and European CE standards, and have been successfully certified under IFT Rosenheim’s QM 328 program.

Fundamental principles of AXOR INDUSTRY’s business

- Professional ethics

- Analysis of strategic and up-to-date information

- Professional and personal development of employees

- Accommodation of customer’s interests and local market specifics

- Impeccable reputation